TESA® Dimple Silicone Tape

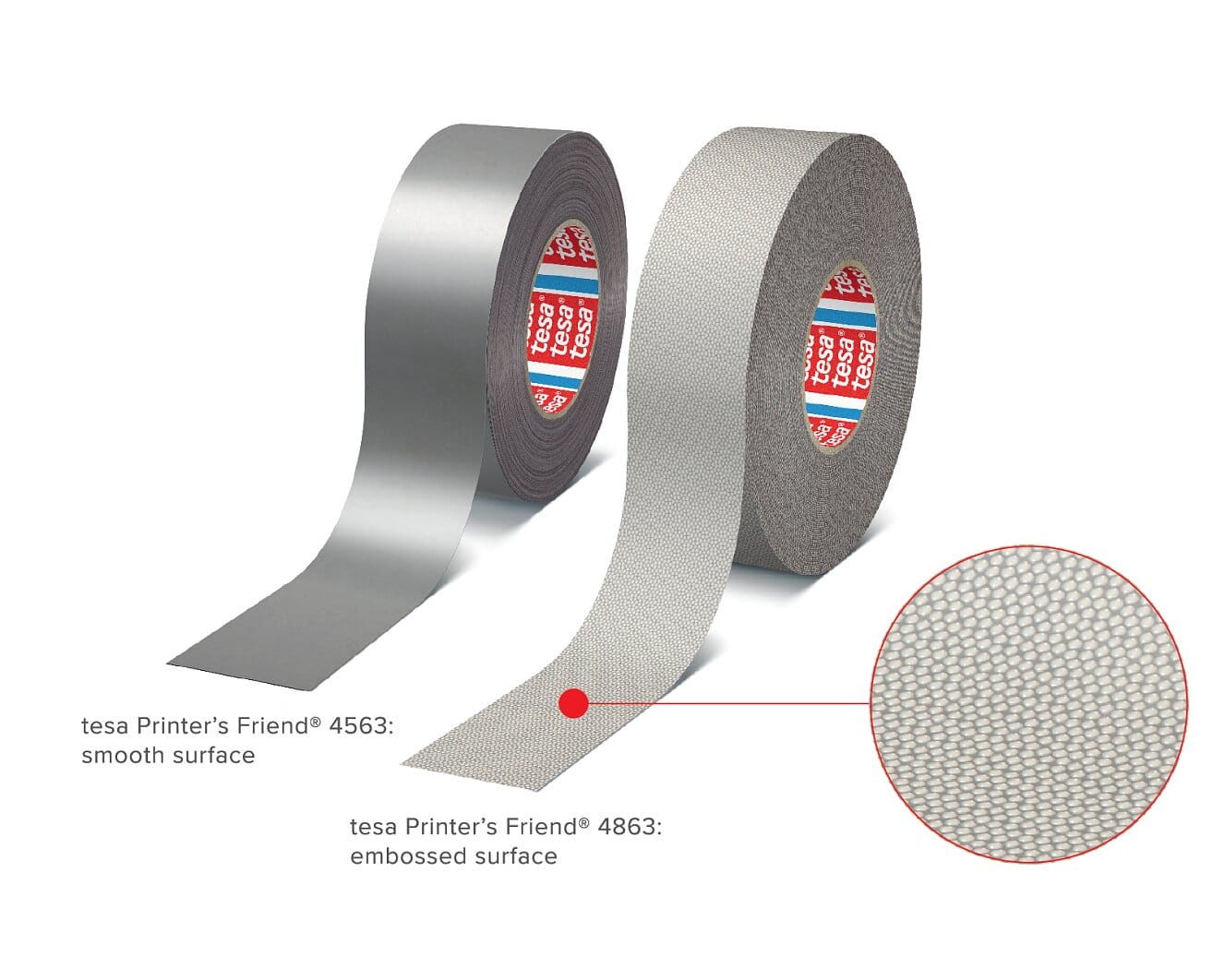

In the demanding world of manufacturing and printing, where precision and durability are essential to avoid interruptions, Tesa® 4863 and 4563 tapes stand out as essential solutions. Known as Printer’s Friend, these silicone-coated fabric tapes transform roller wrapping, combining superior grip and protection in a variety of operations. Manufactured with innovative technology, they are the ideal choice for professionals seeking to maximise efficiency and durability in their equipment

Technical Characteristics TESA® Dimple Silicone Tape

| Property | Tesa 4563 (Smooth Surface) | Tesa 4863 (Embossed Surface) |

|---|---|---|

| Support | Treated rayon fabric (0.34 mm) | Treated fabric (0.35 mm) |

| Coating | Smooth silicone for gentle contact | Embossed silicone (dimples) for extra grip |

| Adhesive | Natural rubber, UV-resistant and resistant to temperatures up to 80°C | Natural rubber, UV-resistant and resistant to temperatures up to 85°C |

| Initial Adherence | ~20 N/25 mm | ~18 N/25 mm |

| Wear Resistance | >500 friction cycles | >600 friction cycles |

| Regulatory Compliance | REACH, RoHS, halogen-free | REACH, RoHS, halogen-free |

Similarities

- Both are silicone-coated fabric tapes, known as Printer’s Friend, designed to wrap rollers in industrial applications such as printing and material processing.

- They offer resistance to adhesive substances, a non-slip effect on smooth surfaces, easy application without dismantling the roller, and residue-free removal after prolonged exposure.

- Toleran temperaturas hasta 80-85°C, cumplen con estándares ecológicos (REACH, RoHS) y mejoran la eficiencia al reducir paradas y desgaste en equipos.

- Ideal for sectors such as printing, textiles and web conversion, with UV-resistant natural rubber adhesive.

Differences

- Tesa 4563 has a smooth surface, optimised for uniform contact and gentle repulsion of adhesives, ideal for delicate substrates such as plastic films.

- Tesa 4863 has an embossed texture (with dimples), which maximises grip on slippery materials, making it the preferred choice for environments with higher friction, such as thick textiles.

- The 4863 withstands slightly more abrasion cycles (>600 vs. >500), but the 4563 offers slightly higher initial adhesion (~20 N/25 mm vs. ~18 N/25 mm).

- In terms of thickness and thermal tolerance, the 4863 is marginally more robust (0.35 mm and 85°C), while the 4563 prioritises smoothness for high-speed applications.

Main Applications

- Label and packaging printing: Wraps traction rollers in digital presses, ensuring flawless alignment in mass production to prevent adhesive defects.

- Plastics and film processing: Covers laminating rollers, repelling sticky polymers and maintaining speeds of up to 100 m/min without deviation.

- Light textile industry: Used on fabric feed rollers, providing firm grip against resins and dyes in continuous finishing lines.

- Web material conversion: Optimises rollers in cutting machines, resisting moisture and abrasion for smooth handling of paper and laminates.

Technical Data Sheets

See our Online Shop:

Another interesting post about TESA® 4952 – 4957 PE Foam Tapes